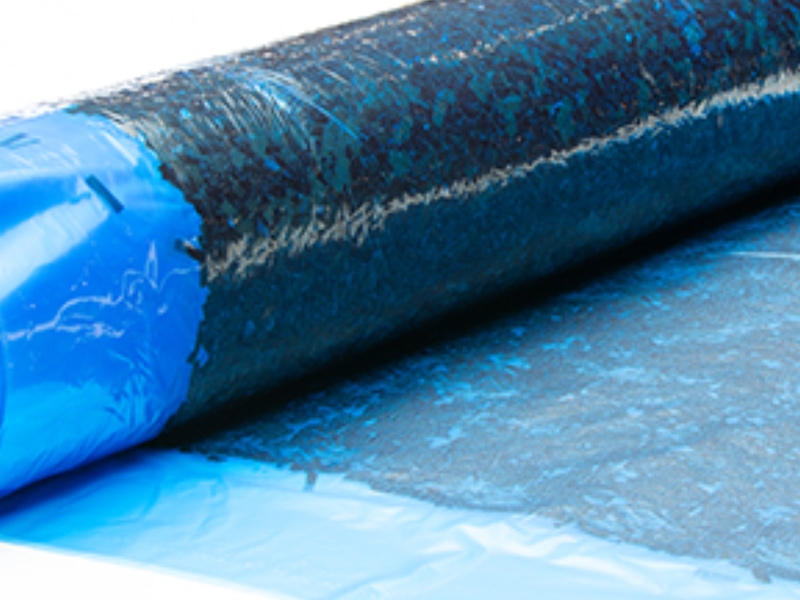

smc composite material (smc) is a semi-finished sheet molding plastic (sheet) produced by smc unit, which is covered with plastic film, resin paste (containing resin, curing agent, thickening agent, filler and some auxiliar…

the appearance of bmc group mesa completely broke the traditional industry low threshold, mixed situation, in order to surpass quartz stone, composite acrylic high hardness, impact resistance, permeability resistance, high …

smc sheet, smc is a composite material, belongs to a kind of glass reinforced plastic. the main raw material consists of gf (special yarn), md (filler) and various auxiliaries.

the d…

jiangsu zaojie new material technology co., ltd. was founded in august 2017, formerly known as shanghai zaojie composite material technology co., ltd. the company specializes in the production of a variety of unsaturated re…

the quality of smc moulded products depends on press equipment, mould, technical parameters and the quality of operators. smc mould quality of good stability, not only from the manufacturing technology and production manage…

1. all lubricating parts should be filled with clean lubricating oil in time.

2. after each shift, dust, oily water and adhesive materials on the surface of the equipment should be w…

1. chemical corrosion resistance: fiber reinforced polyester materials have good corrosion resistance, such as acid, dilute alkali, salt, organic solvent and seawater, while metal materials are not acid and seawater resista…

the following points must be paid attention to when applying thickener to smc sheet:

a. during preparation, the viscosity increase rate is required to be very low to ensure the full …